-

-

Case

-

-

News

-

Technology

-

Contact

We have established a complete mouse and keyboard manufacturing line, from ID design, project integration, R&D, mold development to injection molding, oil spraying, SMT, assembly, and a perfect QC & QA quality control system.

Customer needs as the center, independent research and development of technological advantages, strict quality control system of key points, so that we can provide each of our valued customers with quality products and worry-free service.

Based on excellent model R&D and processing capabilities, under the guidance of the company's strategic positioning, ChuanD has entered the track of rapid development.

Please contact us, we are more than happy to help you!

business scope

业务范围

Mould Making

Professional Mold Team

ChuanD Technology has professional mold design, development and manufacturing capabilities. With innovation as the driving force for development, we have built a professional team of 28 senior mold engineers, equipped with high-end UG/CAD/CAM software systems, with the ability to design, DFMEA, Moldflow analysis and feasibility analysis to support mold development and manufacturing.

Mold development process

1: Feasibility analysis

2: Mold DFM discussion

3: Mold flow analysis

4: 2D and 3D mold construction drawing review

5: Customer's design approval

6: Order of steel material

7: Mold manufacturing

Mold manufacturing

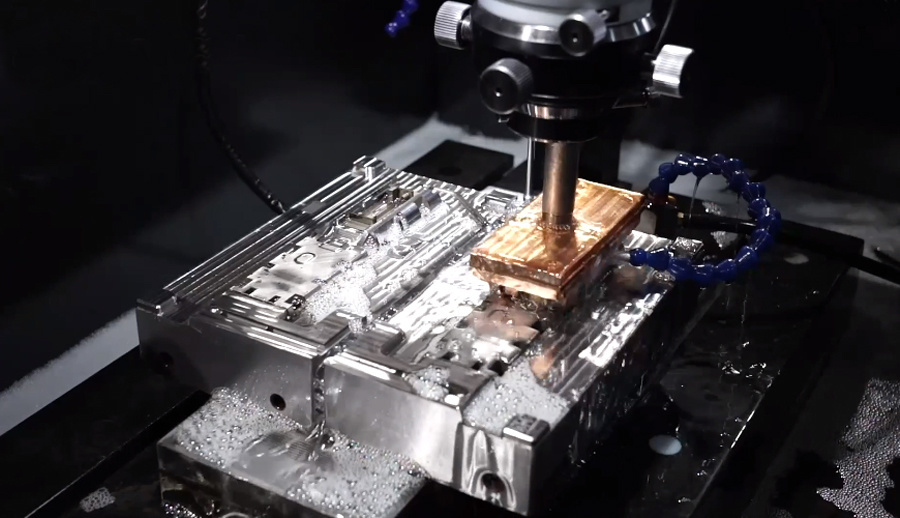

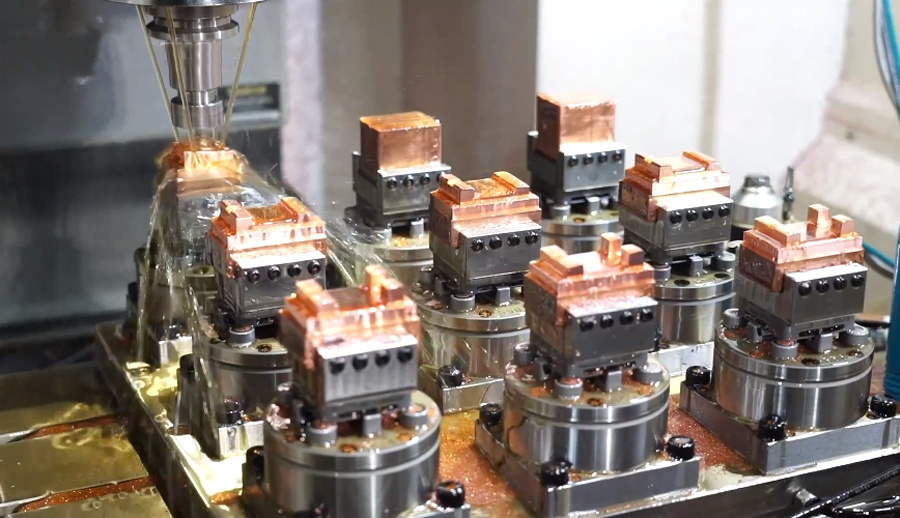

ChuanD Technology has a complete set of high precision foreign imported equipment to effectively guarantee the high quality of molds.

Mold equipment: 7 CNC, 10 spark machines, 7 milling machines, 5 grinding machines, 2 water grinders, 1 lathe, 1 drilling machine, 1 sawing machine, and 6 related measuring and testing equipment.

Mold testing

ChuanD Technology is equipped with injection molding machines from 128 tons to 1000 tons clamping force, which can be used exclusively for new mold trials, further improving the efficiency of mold manufacturing and ensuring better communication with our customers and mold optimization.

The mold trial workshop is equipped with a meeting room where we can discuss and formulate optimization proposals directly with our customers for any issues related to mold trials.

Service hotline:

Name: Martin

Email:bd3@chuand.com

Address:Sijia Xihe Industrial Zone, Shijie Town, Dongguan City, Guangdong Province

GM-Martin